TRACEABILITY SOLUTIONS

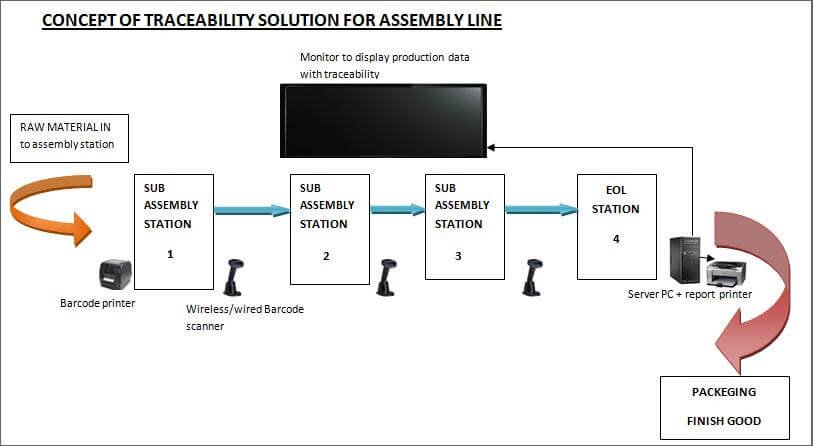

In practice the term traceability stands for a system of computerized record keeping and documentation with report generation by system automation itself, that enables tracking of the movement of a product or ingredient through the production chain till end of line and packaging.

NEED OF TRACEABILITY

Traceability is so important for manufacturers to trace the origins of products. Traceability is highly important within the supply chain, assembly line, end of line of any manufacturer, as it provides the ability to quickly recall products, track production and match replacement parts.

WHAT IT DOES………

In automotive industry, traceability is an process of keeping record of parts and subassemblies associated with a specific vehicle or range of vehicles or assembly parts. The type of information tracked will vary, but some of the more commonly collected information includes.

- Part Number

- Lot Number

- Production Date And Time

- Production Counter

- Model Name

- Operation Name

- Shift

All of this data can be accumulated and combined into a barcode and marked on the part. Barcode readers then decode the data throughout the part’s lifecycle and reliably transfer the information into stand alone server with data log and record facility with report generation.

FEATURES………

- Production Data Log

- Real Time Monitoring

- Cloud Computing Ready

- Report Generation Daily/Monthly

- Traceability For Each Part

- Email Facility For Report