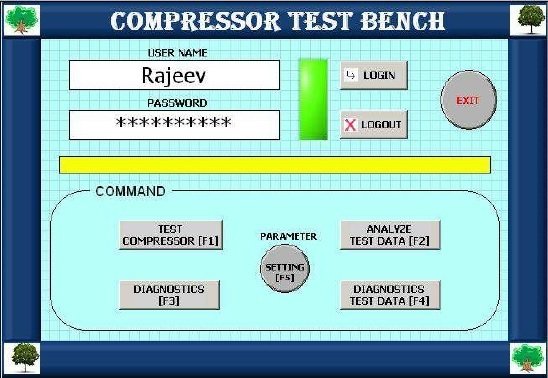

Compressor Test Bench:-

This Test Bench is used to test the Compressors, which has different working principle. There are different types of test which an operator can perform as mentioned below:-

- Functional Test

- Endurance Test

- Air Filling Test

- Heat Run Test

- Noise Test

- Duty Cycle Test

- Starting Test

- Over/Under Voltage Test

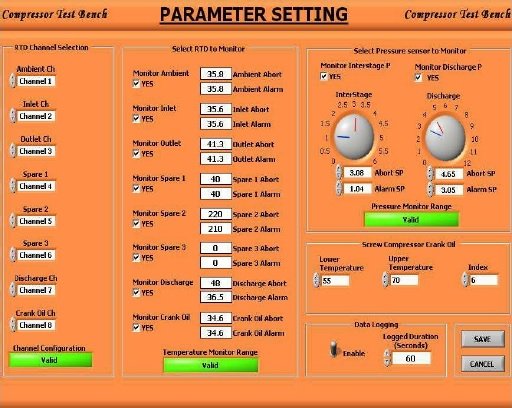

Before starting the test, we need to set the parameters in Setting window as per the type of compressor. First we need to configure the channel to monitor the temperature at various locations with in the compressor. For loading the Compressor, we used a flow control valve. For calculation of FAD (Free Air Delivery), we used pressure sensor at both side of the Nozzle and FAD has been displayed in Lpm on the screen.

The proper safety of Compressor is also

important during its testing. For this we need to

monitor the Interstage pressure (not required in

single stage compressor), Discharge Pressure,

Over Temperature and can set the Alarm set point

& Abort set point.

The Functional test is required for all types of Compressor. The Compressor motor can be start and stop automatically from Front Panel in PC with star-delta starter. Also we can monitor the 3 phase voltage, current, Frequency and power factor with Masibus power meter and data has been recorded in PC as per user specified interval. During the test, if parameter goes beyond safe limit then it will trip the Compressor’s motor and safety Interlock Algorithm will run to ensure full safety of overall system.