Mix Passage and Composition Control:-

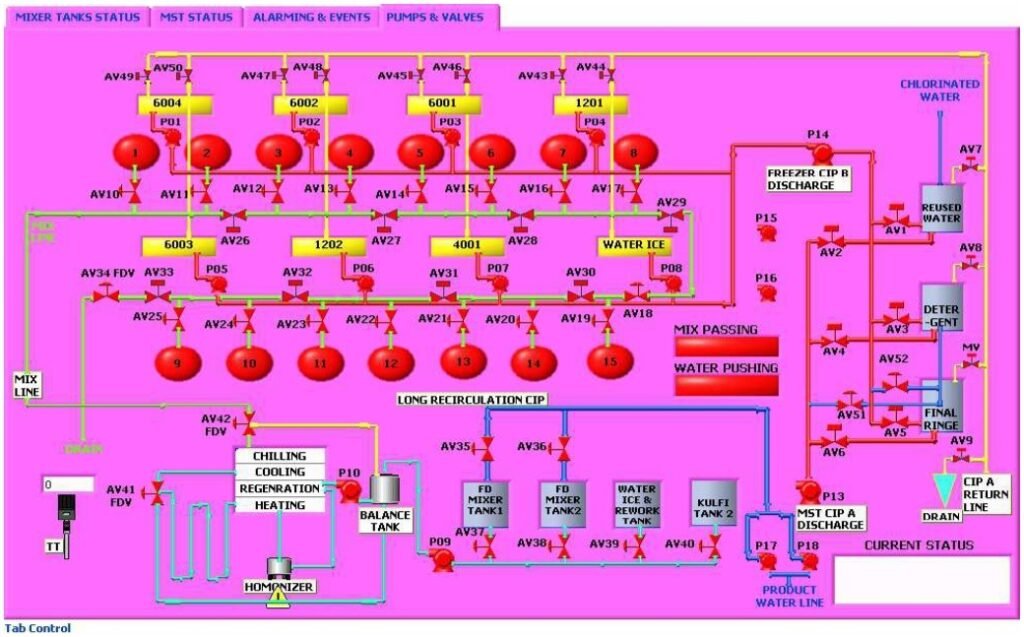

This system was develop to perform CIP (Clean in Plant) process and Composition control of the material in Ice-cream Factory of HUL. There are 15 small tanks and 4 bigger tanks and we need to process CIP of these 15 small tanks in 3 discrete steps. These steps are linked with 3 tanks of reused water tank, detergent tank and final rinse tank at higher temperature. We used 24 V DC operated spring actuated solenoid valve with combination of proximity switch just to take the feedback whether the valve is actually opened or not. For data acquisition and controlling the solenoid valves we use Industrial NI PCI cards.

The task is completed in a defined sequence:

Check Precondition

Initialize

CIP sequence for each Tank

Shut Down CIP

Generate Report and Flag

Send Mails / Save Report

Safety Interlocks are also running in parallel to ensure the safety of overall system. During the operation, Alarms and Events are updated, and display to user in different Tab.